The School of Engineering and Technology congratulates Asst. Prof. Dr. Uthen Thubsuang, a lecturer in the Petrochemistry and Polymer Program, and his research team at Walailak University, for developing activated carbon to be used as a supercapacitor from rubber wood sawdust. This innovation reduces reliance on imports, adds value to Thai rubber biomass, and aligns with the goals of sustainable development.

Asst. Prof. Dr. Uthen Thubsuang explained that the current energy landscape focuses on clean energy, such as electricity, which has increased the demand for energy storage devices like supercapacitors and batteries. The key to high-performance energy storage devices lies in the electrode materials, where activated carbon or carbon has been widely used. Presently, Thailand imports activated carbon suitable for supercapacitors, made from pine sawdust, at a cost of around 2,500 THB per kilogram. In 2020, the global market for supercapacitor-grade activated carbon was valued at approximately $200 million and is expected to grow by 10% annually. In 2019, Thailand’s activated carbon export value exceeded 880 million THB, while imports amounted to over 2 billion THB from countries such as China, Indonesia, Sri Lanka, the United States, Japan, and Germany.

However, Thailand has abundant biomass resources, particularly in the southern region, where rubber plantations are widespread. The rubber industry generates significant biomass annually, including rubber wood sawdust, rubber wood scraps, and waste from rubber processing. This biomass has great potential to be used in producing supercapacitor-grade activated carbon domestically, reducing import costs and adding value to local wood and biomass. This initiative could also boost income for farmers by increasing the demand and price of rubber wood, contributing to sustainable development.

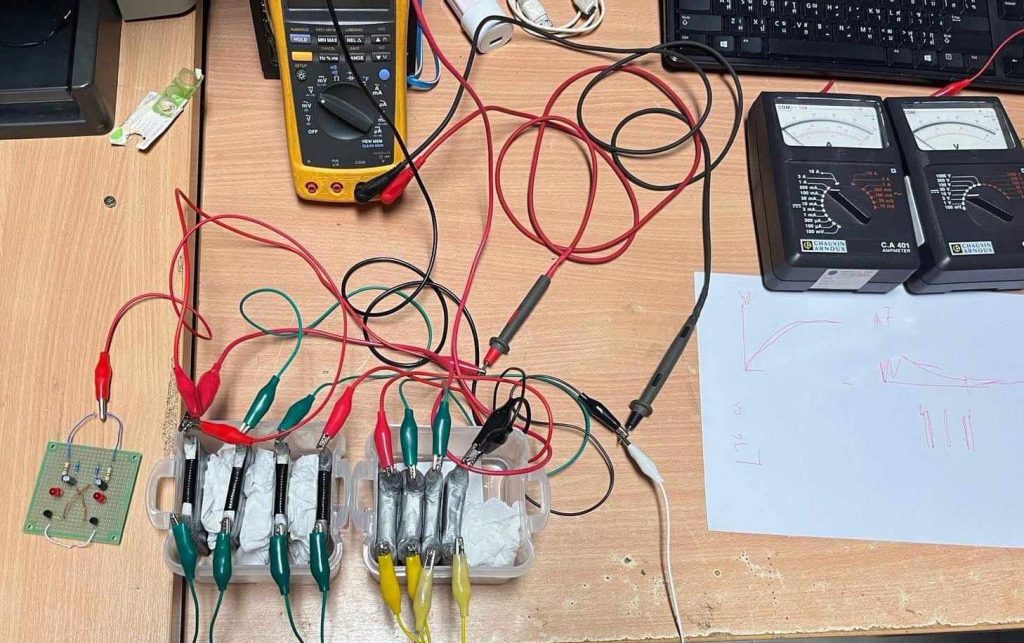

Asst. Prof. Dr. Uthen and his research team have developed a method to create porous carbon from rubber wood sawdust and latex using laboratory-developed processes. These processes create pores in the wood, and when burned, produce activated carbon with high surface area and pore volume, making it highly suitable for storing electric charge. The carbon features a variety of pore structures, such as micropores and mesopores, which are suitable for different applications. The research team has been applying this synthesized porous carbon in energy storage devices, including supercapacitors, fuel cells, CO2 adsorption and conversion to high-value chemicals, and as catalysts for converting biomass and fatty acids into valuable chemicals. This work increases the value of waste from the country’s wood processing industry, with the potential to use the activated carbon as electrodes in supercapacitors, a highly sought-after energy storage device.

Additionally, the research team has explored the development of porous carbon from other biomass sources such as oil palm, biopolymers, and synthetic phenolic resin polymers, which result in carbon with varying properties. They are also investigating other porous materials in the laboratory, such as Metal-Organic Frameworks (MOFs) and Aluminosilicate materials like Zeolites, MCM, and SBA, which are used in adsorption, catalysis, and surface coating applications.

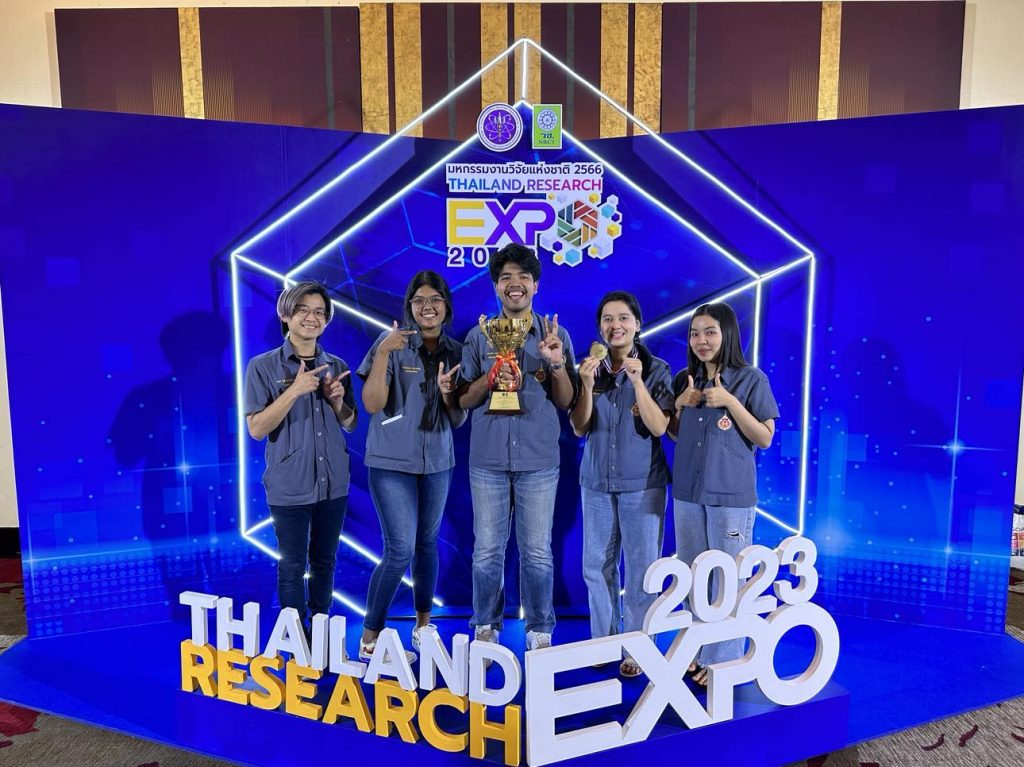

Asst. Prof. Dr. Uthen concluded by highlighting that in the past 2-3 years, this research has received numerous national awards, including the Gold Award at the Thailand Research Expo 2022 and student research awards in porous carbon, such as the first prize in the Startup Thailand League 2023 by the National Innovation Agency (NIA), and the first prize in higher education at The Young Energy Designer Awards 2023, organized by the Department of Alternative Energy Development and Efficiency. The research team expressed their gratitude for the support from various funding sources, including the Rubber Authority of Thailand, the Program Management Unit for Human Resources & Institutional Development, Research and Innovation (PMU-B), and the Thailand Science Research and Innovation (TSRI).